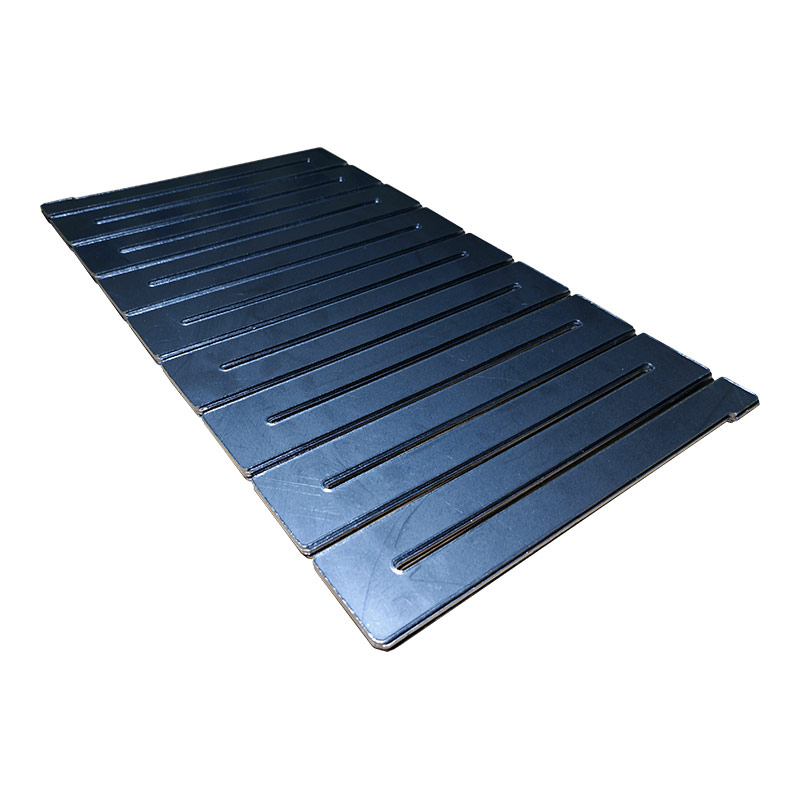

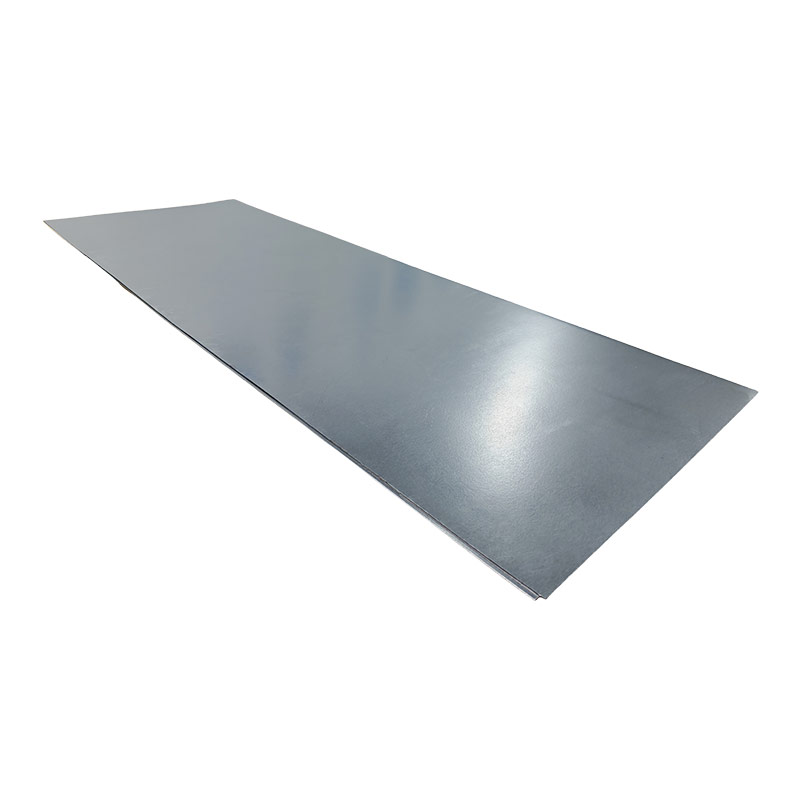

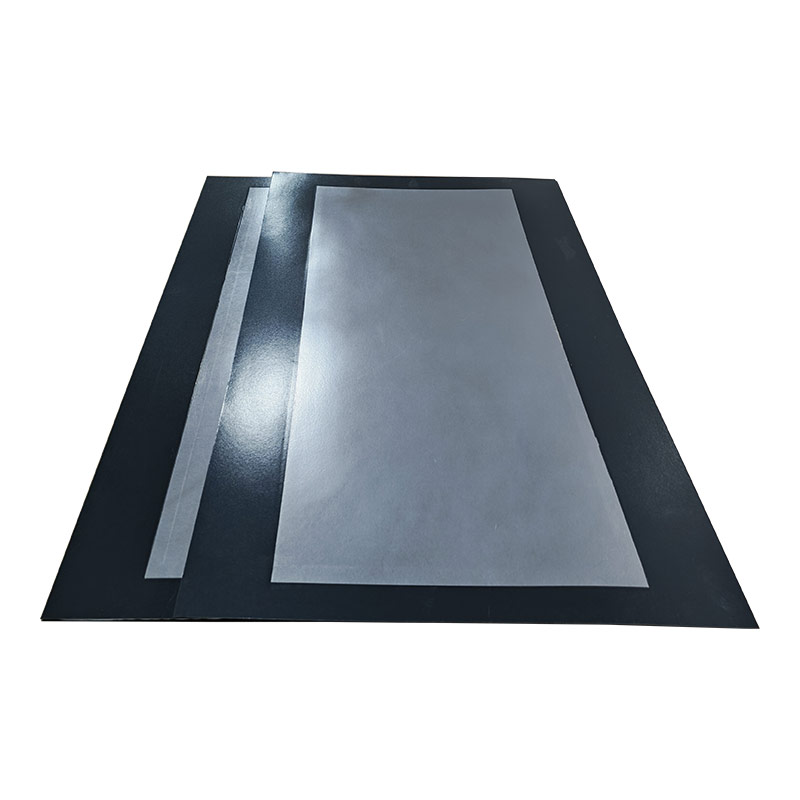

Currently, the flow channel plates used in flow batteries mainly include flexible graphite plates, impregnated flexible graphite plates, and fluorine resin-enhanced flexible graphite plates. Among them, flexible graphite bipolar plates may experience swelling and bubbling due to oxygen and hydrogen evolution at the positive and negative electrodes during use, leading to an increase in overall internal resistance, changes in the compression ratio of the felt body, and increased flow resistance. Even worse, due to the varying sizes and locations of the bubbles, it becomes difficult to control the compression, resulting in poor consistency across the fuel cell stack. Impregnated flexible graphite plates, typically coated with acrylic resin, are not resistant to long-term exposure to electrolyte and electrochemical corrosion. Once the resin on the plate surface is corroded, hydrogen and oxygen will still cause bubbles on the plate surface. For fluorine resin-enhanced flexible graphite plates, PVDF is usually added. The process involves mixing the materials through a cyclone separator, then rolling them into paper, and subsequently hot-pressing to crosslink the PVDF. This process is consistent with that of conventional flexible graphite bipolar plates. Therefore, compared to flow channel plates that often reach thicknesses of 1.6mm, 1.8mm, or even 2mm, it is difficult for the distributor to achieve uniform distribution, and hot-pressing increases costs, making the flow channel plates produced by this process too expensive for mass application. Our company's hard graphite flow channel plates are made by mixing asphalt coke and petroleum coke powder with resin through molding, followed by liquid-phase impregnation and graphitization to produce artificial graphite flow channel plates. These plates are molded in one step, with no other materials added except for carbon, and without interlayer graphite structure. Therefore, these plates do not experience swelling and bubbling due to oxygen and hydrogen evolution at the positive and negative electrodes, offering high stability and relatively low cost. These plates have been validated in highly corrosive and high hydrogen evolution systems such as zinc-bromine flow batteries and iron-chromium flow batteries, demonstrating excellent stability. They are currently the most stable flow channel plates for flow batteries.

Rigid runner plate

|

Carbon content |

Resistance value (Square resistance) |

Specific conductance |

Thickness |

Work temperature |

Density |

|

≥99% |

5-10mΩ |

≥1000S/cm |

1.5-3mm |

-60-450℃ |

1.75-1.9g/cm³ |

Special note:This flow channel plate completely solves the problem of bubble bubbling and can be stably used in iron chromium systems that are prone to hydrogen evolution and zinc bromine systems with strong corrosiveness.

English

English  中文简体

中文简体