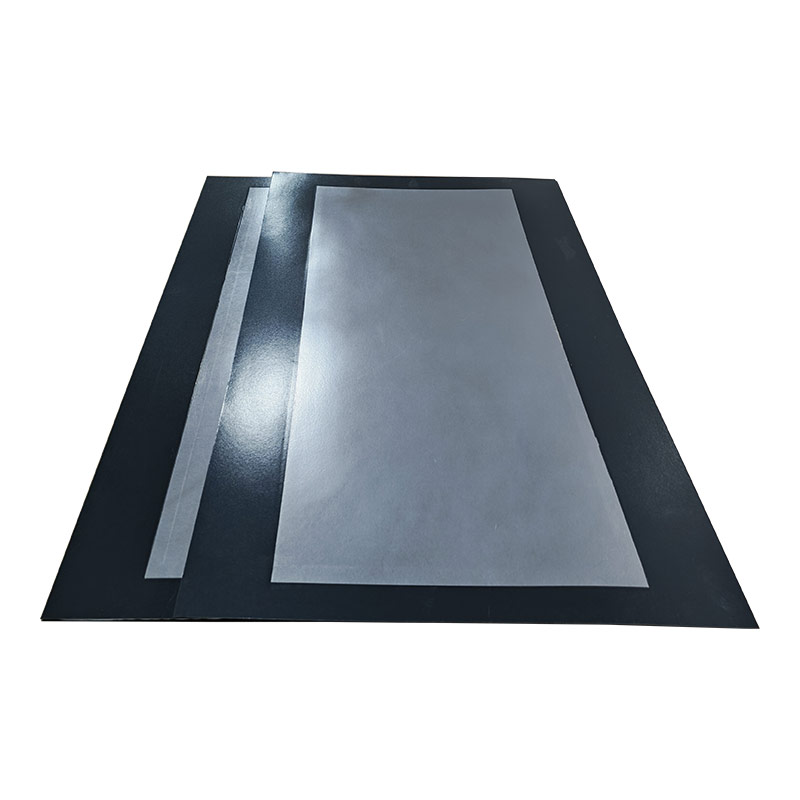

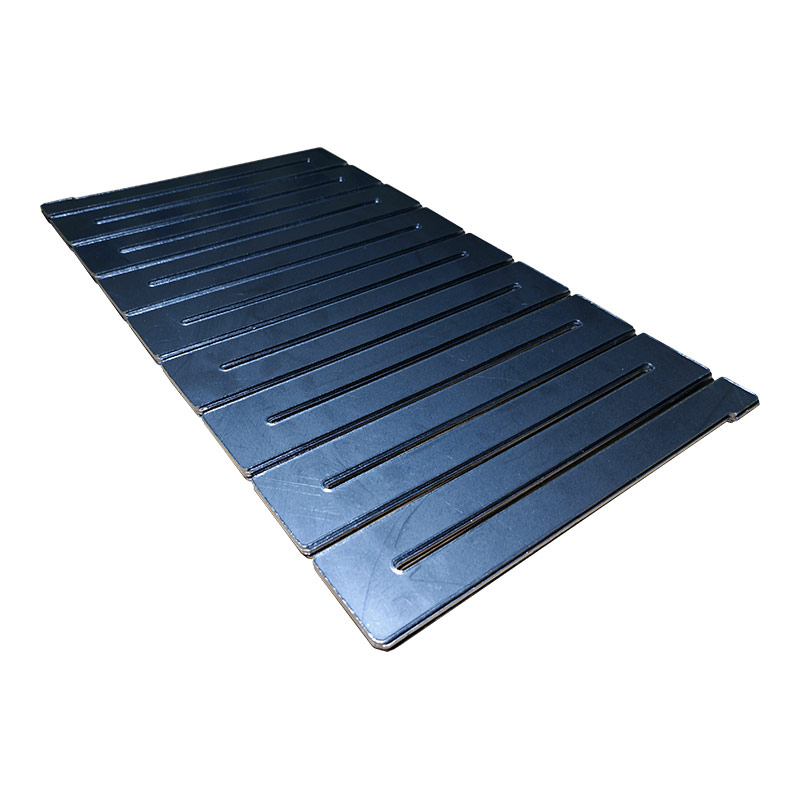

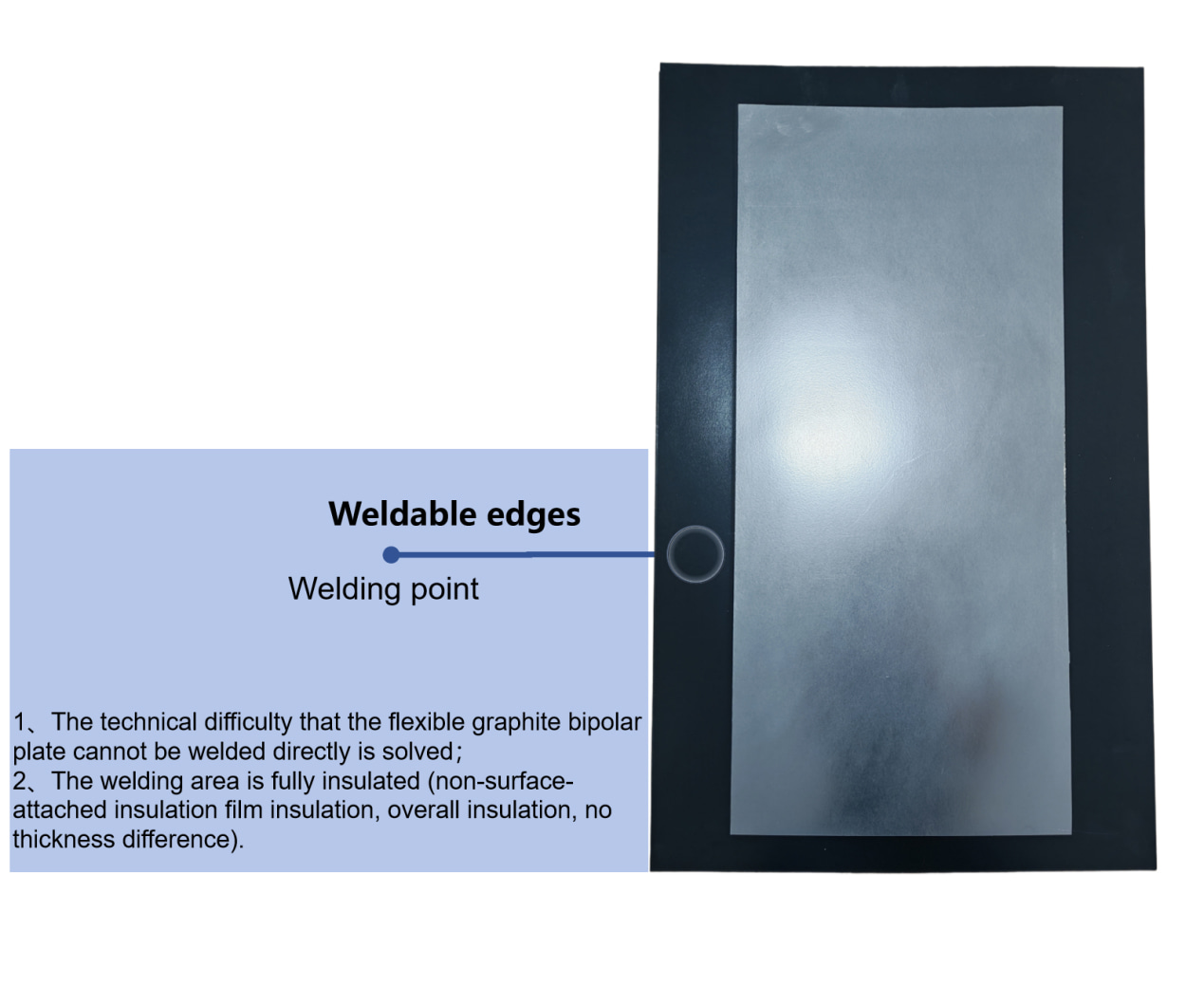

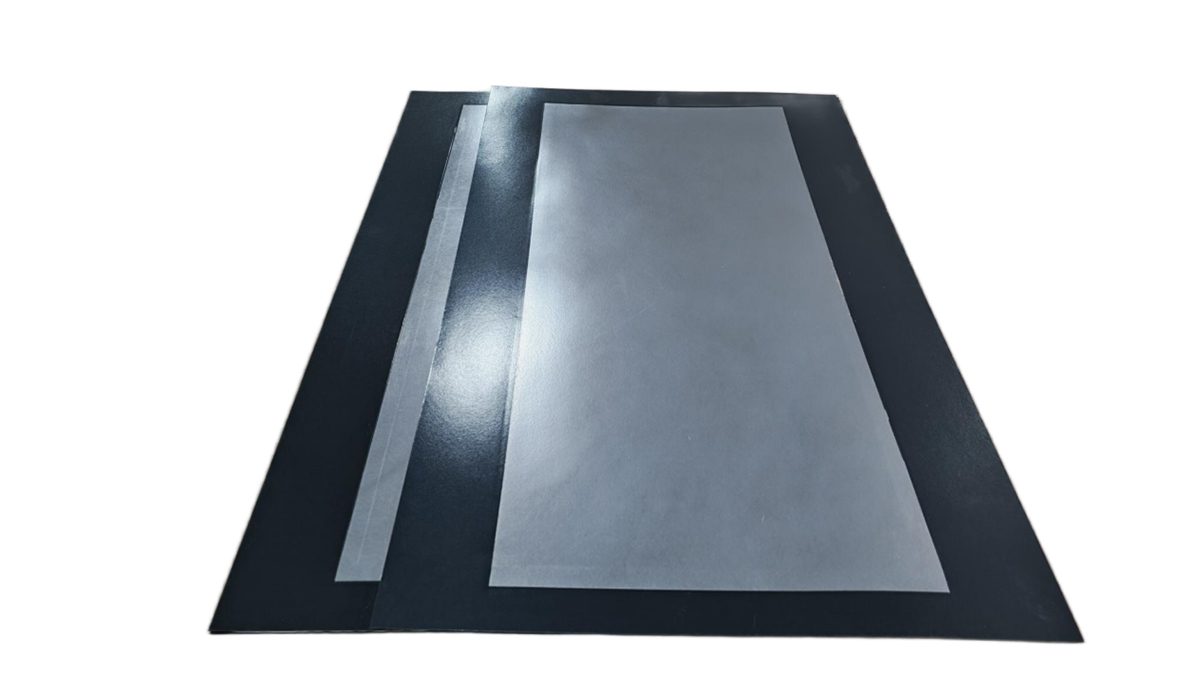

Currently, there are two welding processes for bipolar plates in flow batteries. One is to bond the bipolar plate and the plate frame together using hot melt adhesive. This welding process is commonly used in scenarios involving flexible graphite bipolar plates, but hot melt adhesive has issues such as low-temperature debonding and limited corrosion resistance lifespan. The other is to use carbon-plastic bipolar plates, which are directly melted using laser heat fusion, allowing them to be welded directly onto the plastic plate frame. This process offers superior welding strength and service life, but the conductivity of carbon-plastic bipolar plates is poor. As the current density of flow batteries continues to increase, the conductivity of carbon-plastic bipolar plates fails to meet the requirements. Our bipolar plate process incorporates a framework, which extends and allows plastic that can be welded using laser heat fusion to adhere to the framework. Through special structural design, the plastic is tightly integrated with the graphite conductive area in the middle. This process enables this type of bipolar plate to combine the conductivity of flexible graphite bipolar plates with the strong and laser-weldable properties of carbon-plastic bipolar plates. This unique technology and excellent performance represent a unique innovative design in flow battery electrode materials. Moreover, the welding edge framework of this structure can be replaced with an insulating material framework, ensuring that any drilled cross-section is insulated and eliminating the need for insulating washers. Due to its insulating properties, the welding edge can be fused with the plate frame, creating an integrated bipolar plate and frame structure. This type of bipolar plate represents a disruptive innovation in the industry and will promote its development to a certain extent.

English

English  中文简体

中文简体