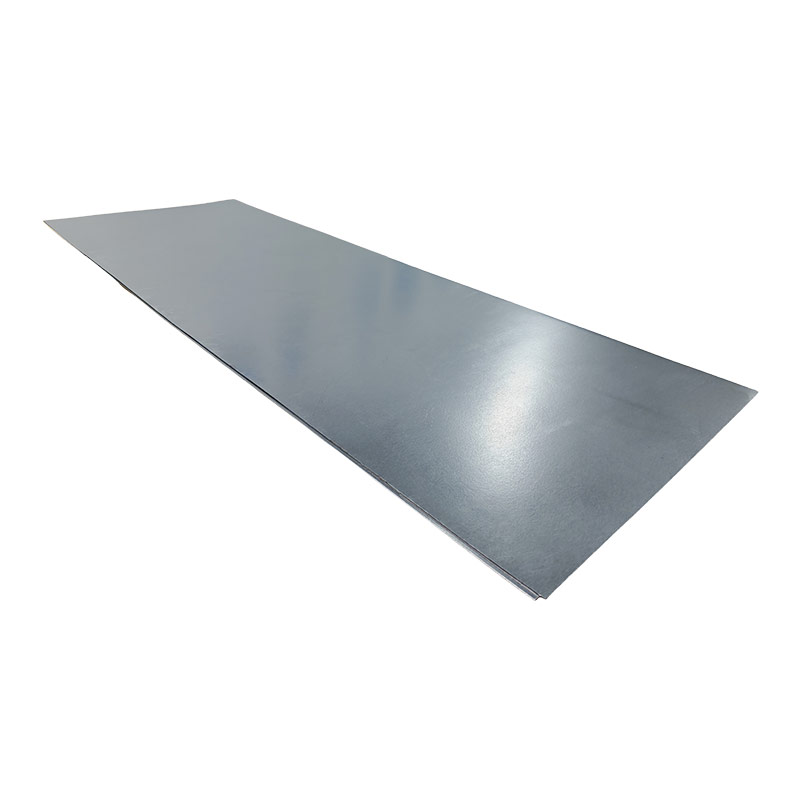

The electrodes of flow batteries are generally made of electrode felt and electrode cloth. The process involves making the pre-oxidized fiber into felt or cloth through textile technology, followed by carbonization, graphitization, and activation to produce the electrodes. The most critical step affecting the performance of the electrode material is the activation step. The conventional activation process is carried out through oxidation activation, typically involving high-temperature heat treatment with air or air mixed with some water vapor, to graft different active functional groups (usually hydroxyl and carboxyl groups) onto the surface of the carbon fibers, achieving hydrophilic effects. Due to oxidative etching, the specific surface area of the carbon fibers is increased, and the active sites are enhanced, thus producing well-activated hydrophilic electrode materials. This process is characterized by simplicity, convenience, and low cost. However, it has the disadvantage of being unable to accurately control the proportion and quantity of oxygen-containing functional groups. The chemical bonds of hydroxyl and carboxyl groups on the carbon fibers are prone to breakage and deactivation; the oxidation activation process leads to the appearance of oxidized graphite on the surface of graphitized carbon fibers, resulting in poor conductivity; the specific surface area increase due to the oxidation activation process is extremely low, usually not exceeding 2 m²/g, and the increase in reaction sites is relatively small.

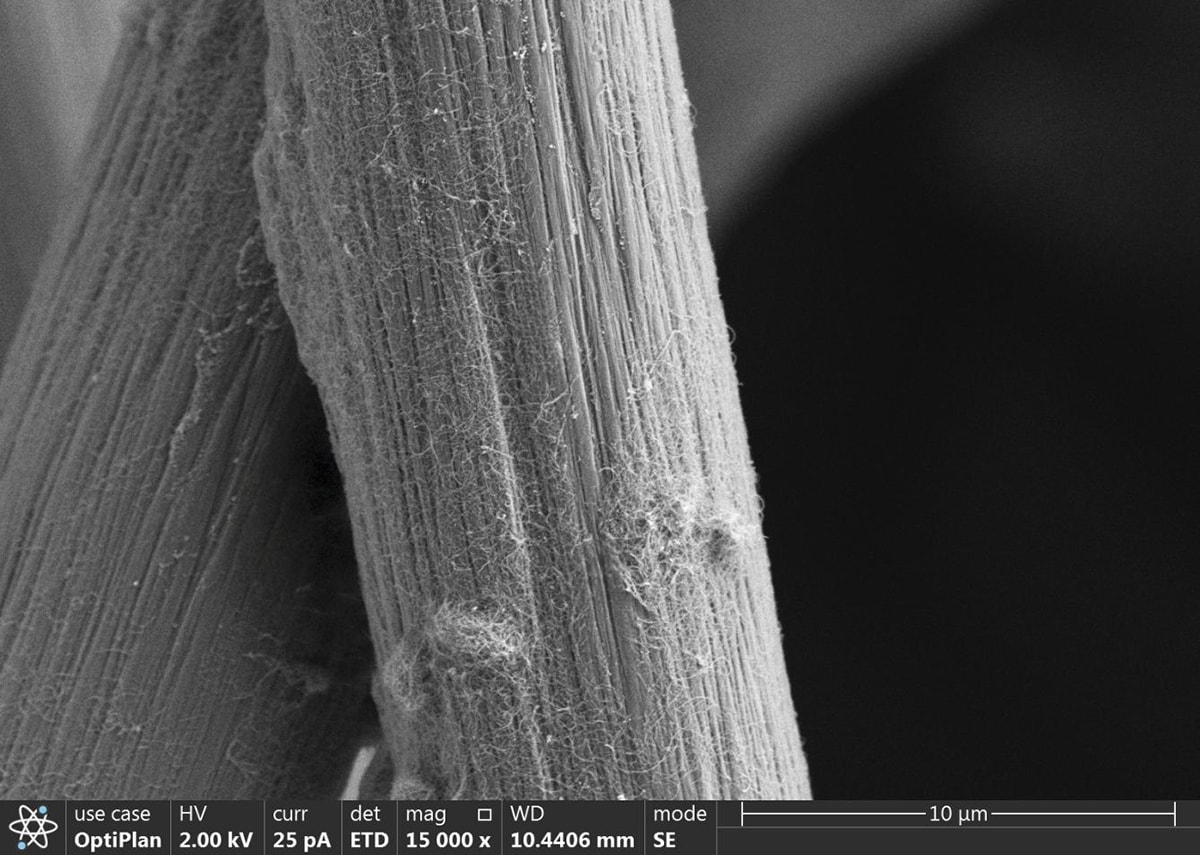

Our activation process involves depositing carbon nanotubes onto the surface of graphitized carbon fibers through a continuous vapor deposition process. By controlling the gas flow and pressure conditions, the carbon nanotubes are uniformly coated on the surface of the carbon fibers (due to the absence of catalysts, the carbon nanotubes can only adhere and grow on the carbon fibers, which in turn results in a tight coating of carbon nanotubes that does not fall off). Then, through nitridation, pyrrole and pyridine structures are grafted to inhibit the hydrogen evolution side reaction. Finally, oxidation reactions occur in several temperature zones to graft oxygen-containing functional groups onto the surface.

The characteristics of this process are:

1. The capillary phenomenon formed by depositing carbon nanotubes achieves hydrophilic effects through a physical method, making it less prone to deactivation;

2. The specific surface area is large, typically ≥10㎡/g, which is 5-10 times that of conventional processes;

3. There is minimal oxidation etching, and the internal resistance of the electrode is low. This process differs from conventional oxidation activation methods that damage carbon fibers. Not only does it not damage carbon fibers, but it also helps to increase the conductivity and strength of carbon fibers, and can even produce hard electrodes through high deposition. Generally, the voltage efficiency of a 2.5mm electrode is generally ≥88%, while that of a 4.35mm thick electrode is generally ≥87%, demonstrating excellent performance. Our company has the first continuous CVD vapor deposition furnace in China, which is used for in-situ growth of CNTs through CVD vapor deposition. It has undergone over 10,000 cycles with a cycle loss of ≤0.5%. The specific surface area of electrode felts and electrode cloths is typically around 12㎡/g, with the highest achievable being 600㎡/g. The CNTs have a diameter of 8-10nm and a length of 100-200nm.

| Name | Unit | Electrode cloth | Electrode felt | Remarks | |||||||

| ① | ② | ③ | ① | ② | ③ | ④ | ⑤ | ||||

| Thickness | mm | 0.6±5% | 0.8±5% | 0.9±5% | 2.5±7.5% | 4.35±7.5% | 5.0±7.5% | 6.0±7.5% | 7.0±7.5% | Other specifications can be customized according to customer needs |

|

| Model number | - | OEPLG-XX4235-7.5 | OEPLG-XX4542-7.5 | OEPLG-XX3543-7.5 | OEPLG-2.57.5 | OEPLG-4.356.5 | OEPLG-5.06.5 | OEPLG-6.06.5 | OEPLG-7.06.5 | ||

| Density | g/cm³ | 0.3-0.4 | 0.08-0.11 | ||||||||

| Width | m | 1.3-1.5 | 1.42-1.45 | ||||||||

| Breaking strength |

Radial |

N | ≥20 | ≥10 | |||||||

|

Zonal |

≥30 | ≥10 | |||||||||

| Thermal conductivity |

Vertical | W/m·k | 5 | 0.28 | |||||||

| Square resistance value |

Ω/口 | 0.12-0.4 | 0.2-0.5 | ||||||||

| Carbon content | % | ≥99.90 | ≥99.90 | ||||||||

| Liquid carrying rate | ×100% | 9 | 10 | 11 | 22 | 12 | 14 | 11 | 11 | ||

| Fiber shedding rate |

% | ≤0.5 | ≤0.5 | ||||||||

| Specific surface area |

m²/g | 9-15 | 9-15 | ||||||||

English

English  中文简体

中文简体