Conductive Hot Melt Adhesive Web Film

Product

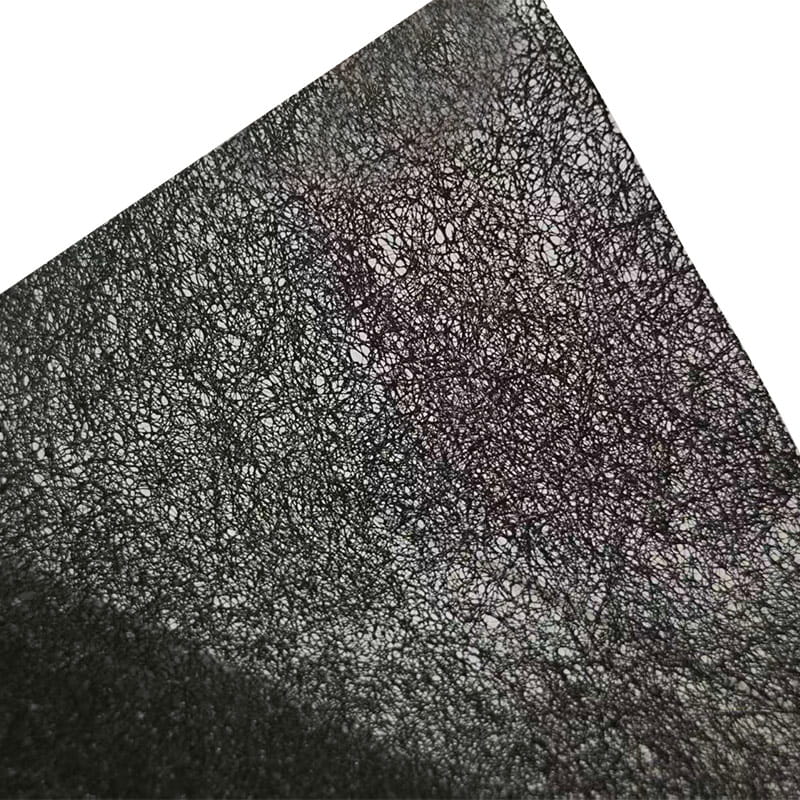

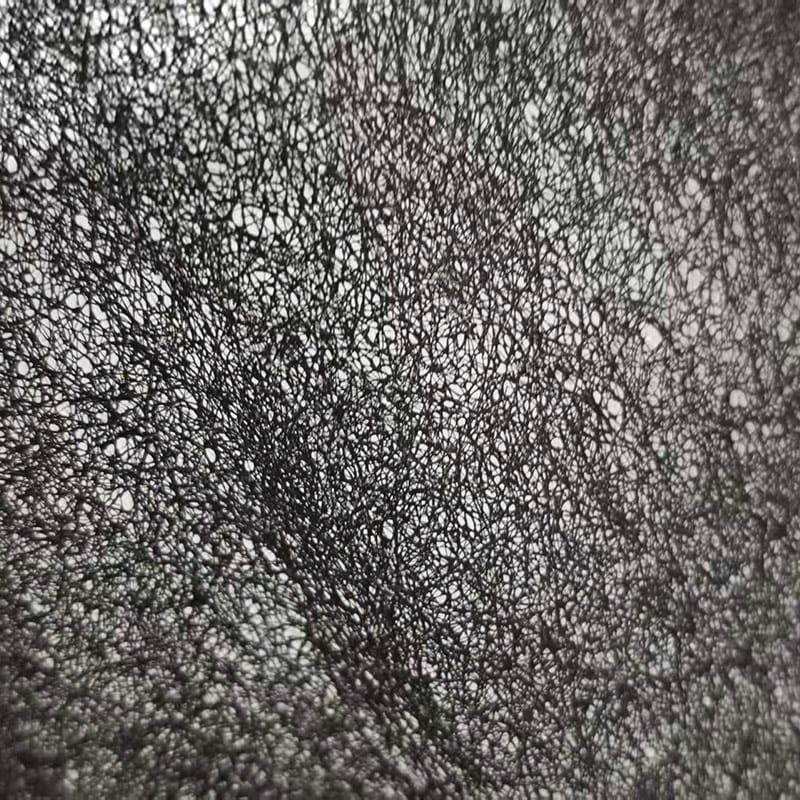

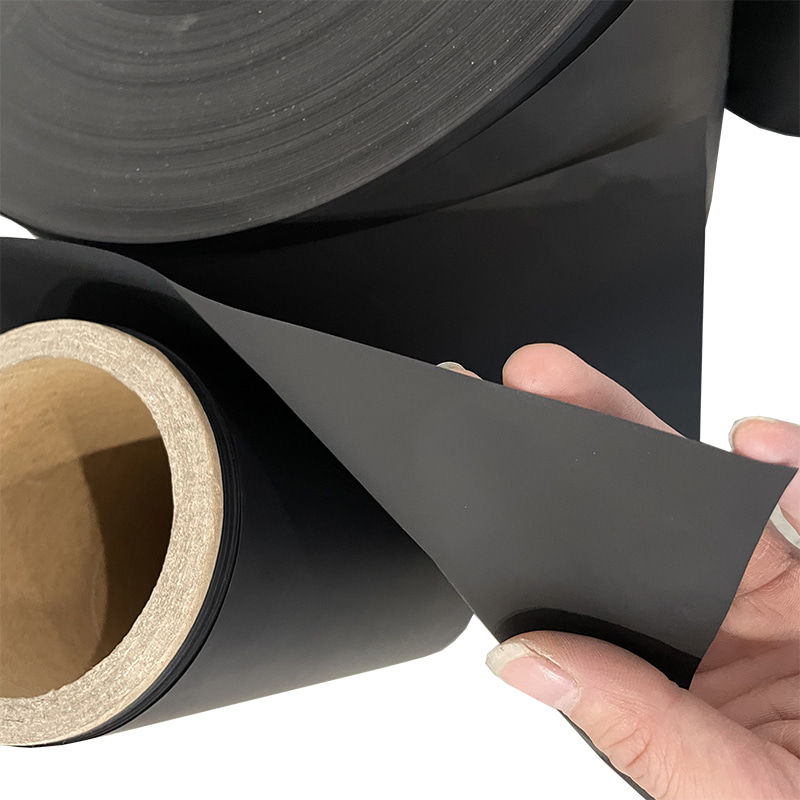

Carbon nanotubes with a diameter of 8-10nm and a length of 10-15μm, POE and other excipients are mixed through an internal mixer and then granulated. The fabricated particles are processed into meltblown fabric through a meltblown machine. It features high electrical conductivity, high acid and alkali resistance, and high resistance to electrochemical corrosion. Moreover, it begins to have good adhesiveness at 80℃. The electrical conductivity of the material after its hot melting and subsequent cooling is greater than 30 seconds /cm, demonstrating excellent electrical conductivity. It is an excellent material for reducing the contact resistance of two solid materials of electrode materials inside batteries.

- Product Details

- Contact Us

| Name | Unit | Conductive hot melt adhesive web film |

| Thickness | mm | 0.1-0.3 |

| Density | g/cm³ | 0.2-0.3 |

| Width | mm | ≤1200 |

| Length | mm | - |

| Extension strength | Mpa | ≥0.1 |

| Compressive strength | Mpa | ≥0.5 |

| Conductivity in the conductive area | S/cm | ≥30 |

| Electrical conductivity in the welding area | S/cm | - |

| Carbon content | % | ≥40 |

| Hydrogen transmission rate(0.2Mpa) | cm3/cm2·min | - |

| Corrosion current | A | - |

Related Products

About us

Jiaxing Naco New Material Co.,Ltd.

Jiaxing Naco New Material Co., Ltd. / Bohe New Material Co., Ltd. (Jiaxing/Nanchang) was co-founded by the Institute of New Energy Jiashan, Zhejiang Fangxiang Group, and Guangdong Haihua Technology. Jiaxing Naco New Material Co., Ltd. is China Wholesale

Conductive Hot Melt Adhesive Web Film Manufacturers and Electrically Conductive Fabric Suppliers. The company is dedicated to the R&D, production, and sales of special carbon electrode materials and products, providing customers with optimized process solutions. Our products are applied in industrial sectors such as water electrolysis for hydrogen production, flow batteries, zinc-ion batteries, air batteries, and high-temperature thermal fields. We offer Woven Conductive Fabric for sale.

Learn more

English

English  中文简体

中文简体