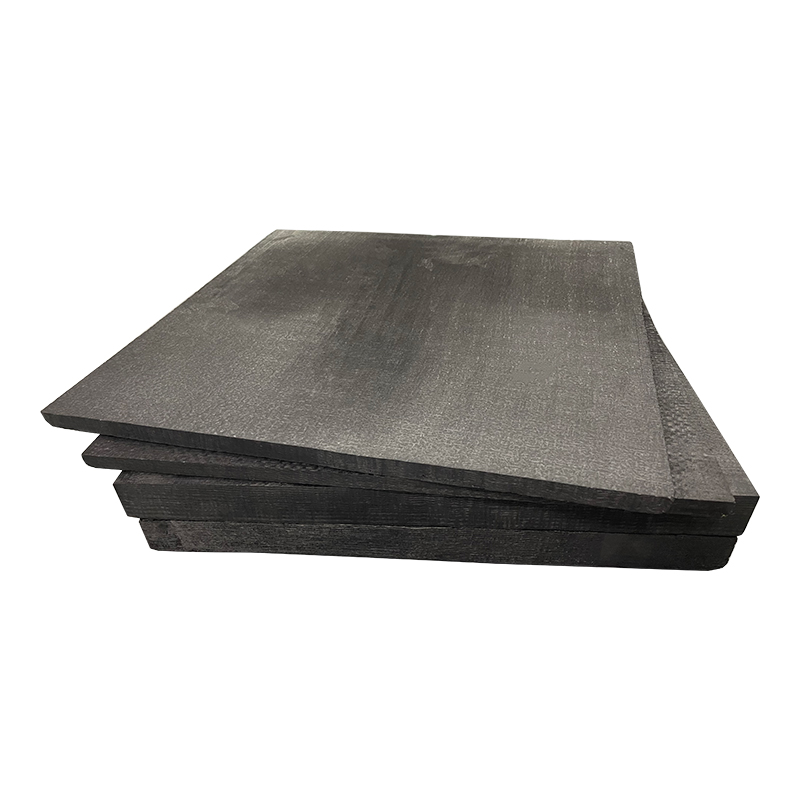

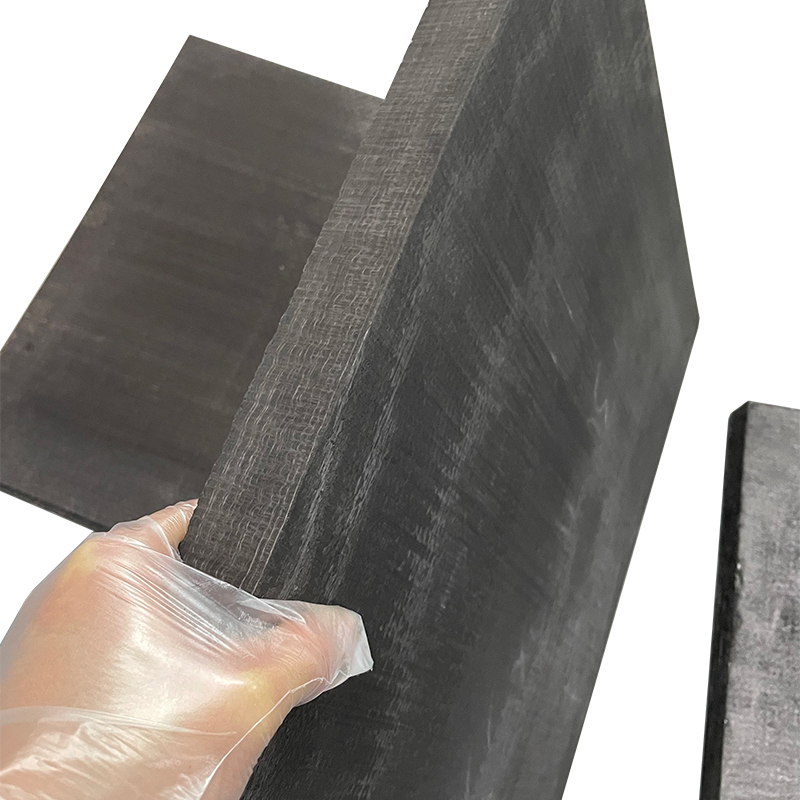

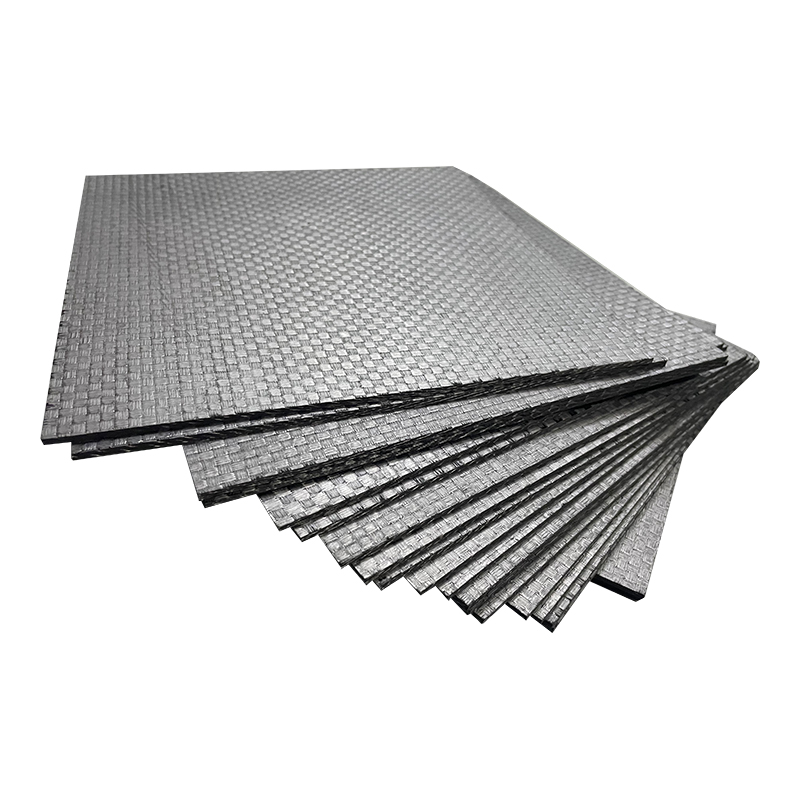

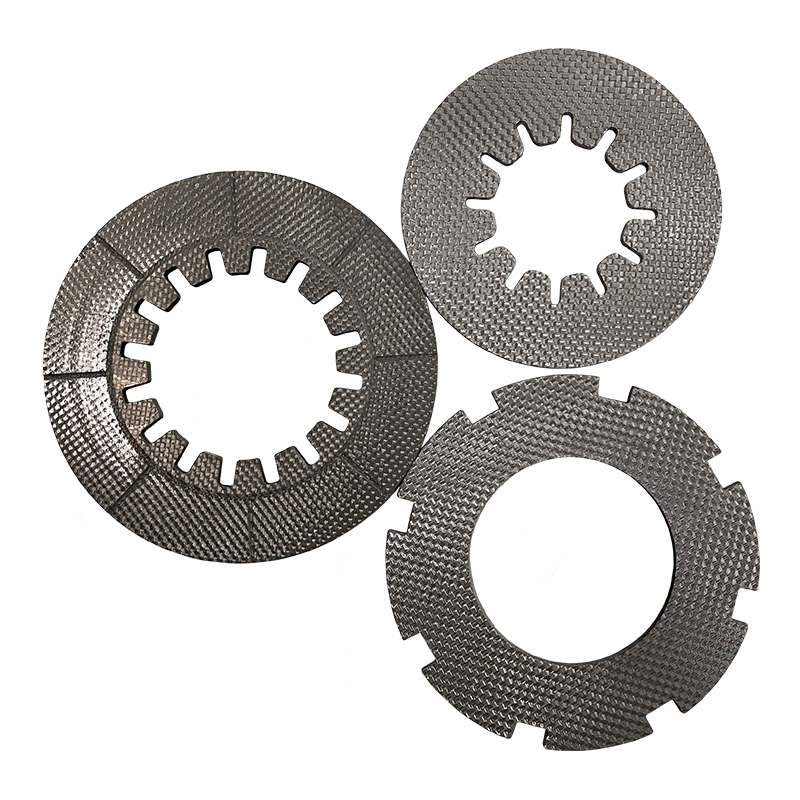

Carbon-Carbon Composite Materials

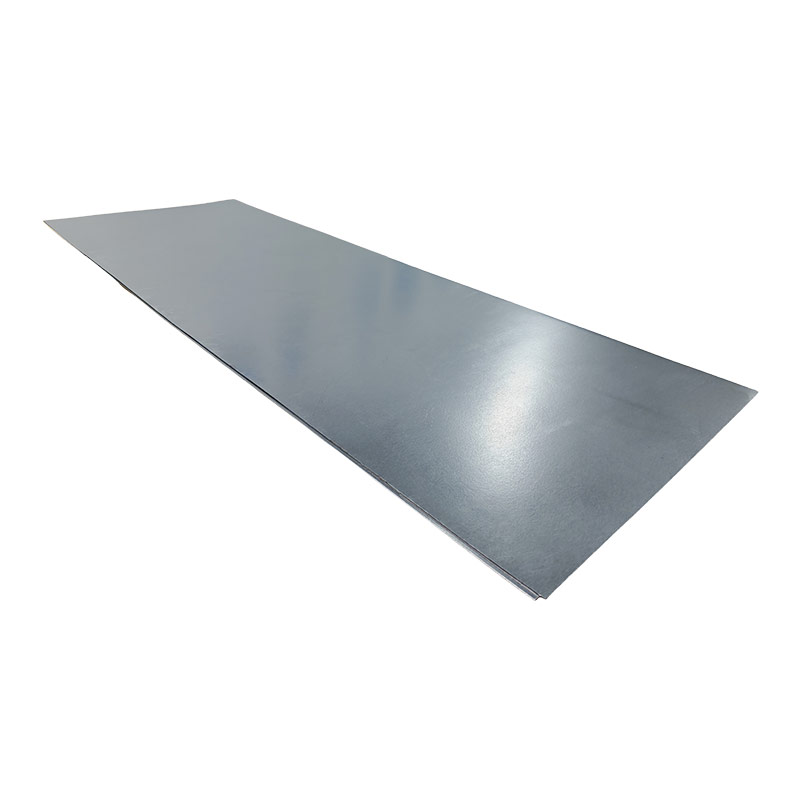

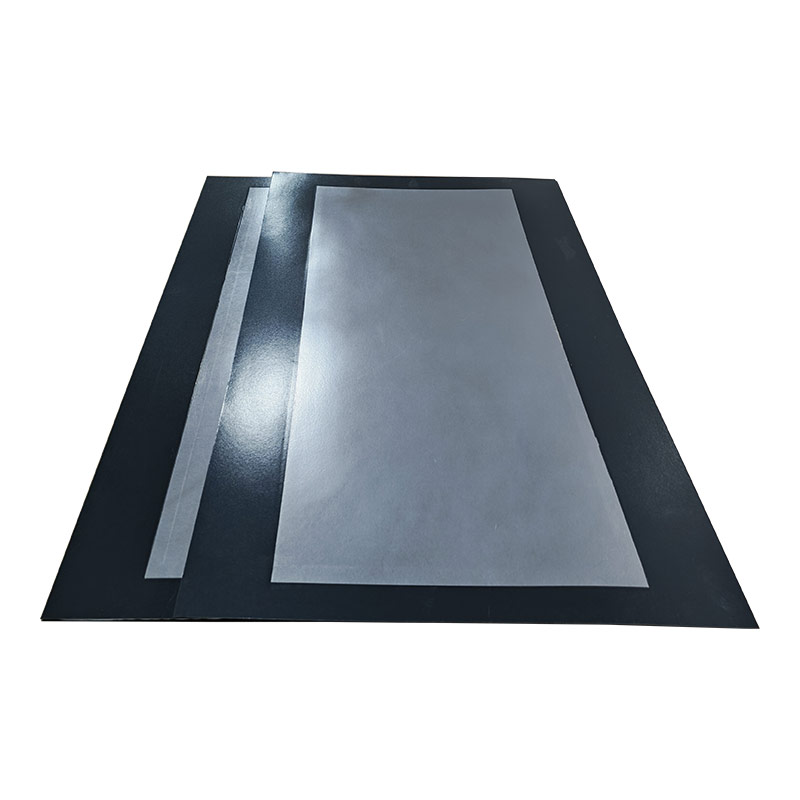

Carbon-carbon composite materials refer to a pure carbon multiphase structure composed of carbon fibers or their fabrics as reinforcing phases and chemically gas-permeated pyrolytic carbon or liquid-phase impregnated - carbonized resin carbon and asphalt carbon as matrices. It has the advantages of low density, low coefficient of thermal expansion, good high-temperature mechanical properties and high specific strength, making it a candidate component for thermal structures. It is lightweight, with a density of 1.65-2.0g/cm ³, which is only a quarter of that of steel. The mechanical properties increase with the rise in temperature (before 2200℃), and it is an engineering material that can maintain high-temperature strength above 2200℃. It has a small coefficient of linear expansion and good high-temperature dimensional stability. Excellent ablation resistance; High damage tolerance and excellent thermal shock resistance. It has good friction characteristics, a stable friction coefficient, and can be adjusted within the range of 0.2 to 0.45. It features a high load-bearing capacity and strong overload capacity, and can withstand temperatures below 3200℃ for a long time without any bonding phenomenon at high temperatures. It has a long service life, and under the same conditions, the wear amount is approximately 1/3 to 1/7 of that of powder metallurgy brake materials. It has a high thermal conductivity and a large specific heat capacity, making it an excellent material for heat storage. Excellent fatigue resistance; Has a certain degree of toughness; It is convenient for maintenance. It is widely applied in fields such as photovoltaic semiconductors, metallurgy, heat treatment, friction structural components, and high-temperature structural components. We can provide various shapes such as plates, discs, cylinders, special-shaped structures, bolts, nuts and fasteners.

- Product Details

- Contact Us

| Name | Unit | Carbon-carbon composite material | Remarks | |

| Thickness | mm | 1.2-200 | Other specifications can be customized according to customer needs |

|

| Density | g/cm³ | ≤1.8 | ||

| Width/Diameter | mm | ≤1800 | ||

| Length/Height | mm | ≤2400 | ||

| Extension strength | Mpa | ≥90 | ||

| Compressive strength | Mpa | ≥120 | ||

| Thermal conductivity | W/m·k | 1200℃ | ≤35 | |

| 1500℃ | ≤5 | |||

| Carbon content | % | ≥99.80 | ||

| Heat treatment temperature | ℃ | ≥1800 | ||

| Ash content | ppm | ≤200 | ||

Related Products

-

Carbon Fiber Reinforced Composite Flexible Graphite Bipolar Plate

-

Carbon Fiber Reinforced Composite Flexible Graphite Bipolar Plate With Welded Edges

-

Carbon Fiber Reinforced Carbon-Plastic Bipolar Plate

-

Carbon Nanotube Powder

-

Carbon Black Powder

-

Polyacrylonitrile (PAN) -Based Carbon Cloth Graphite Cloth

English

English  中文简体

中文简体