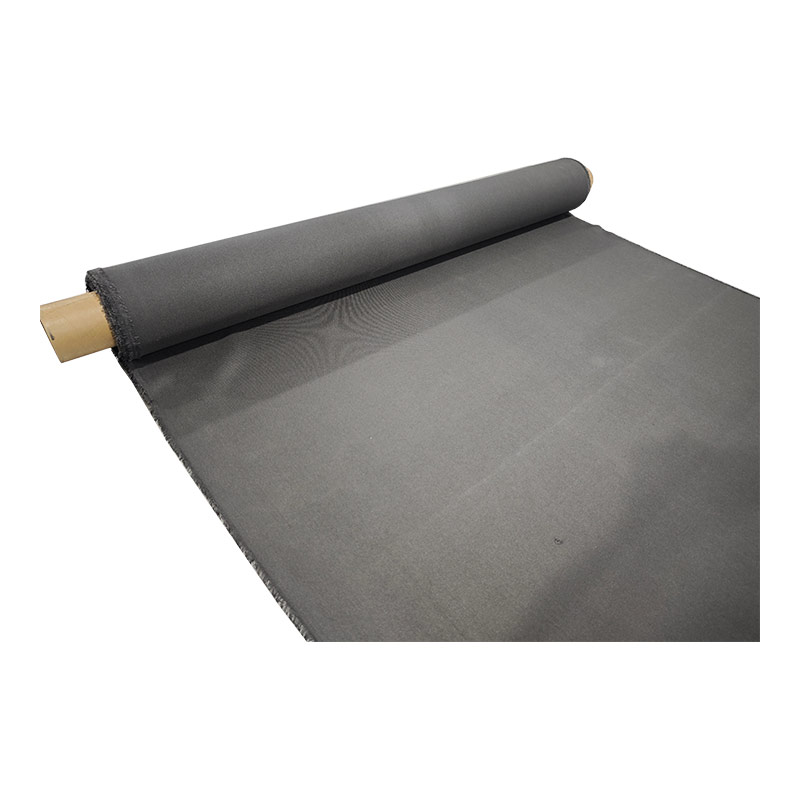

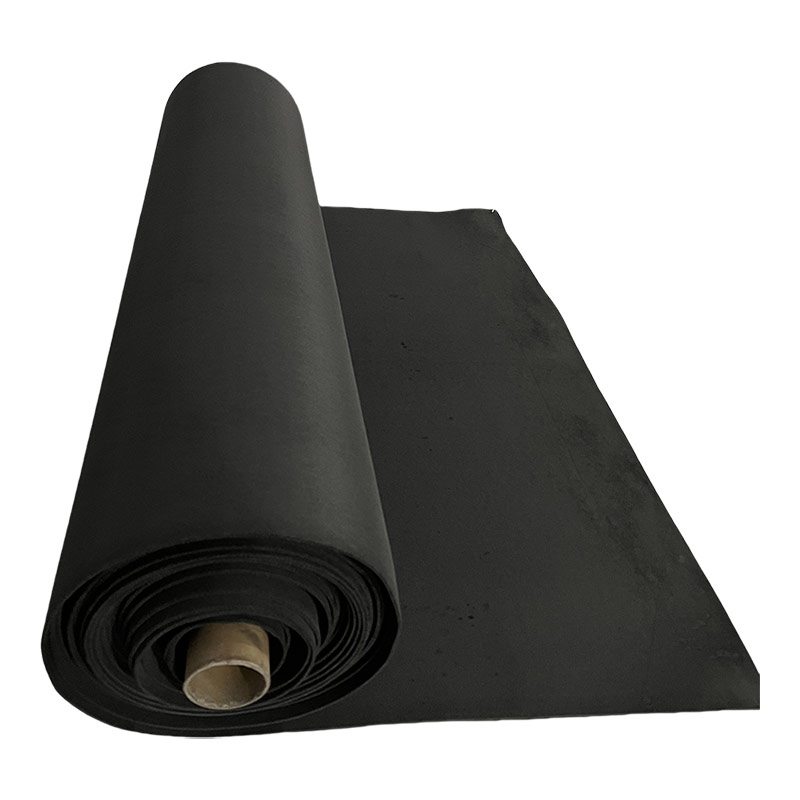

Electrode Cloth

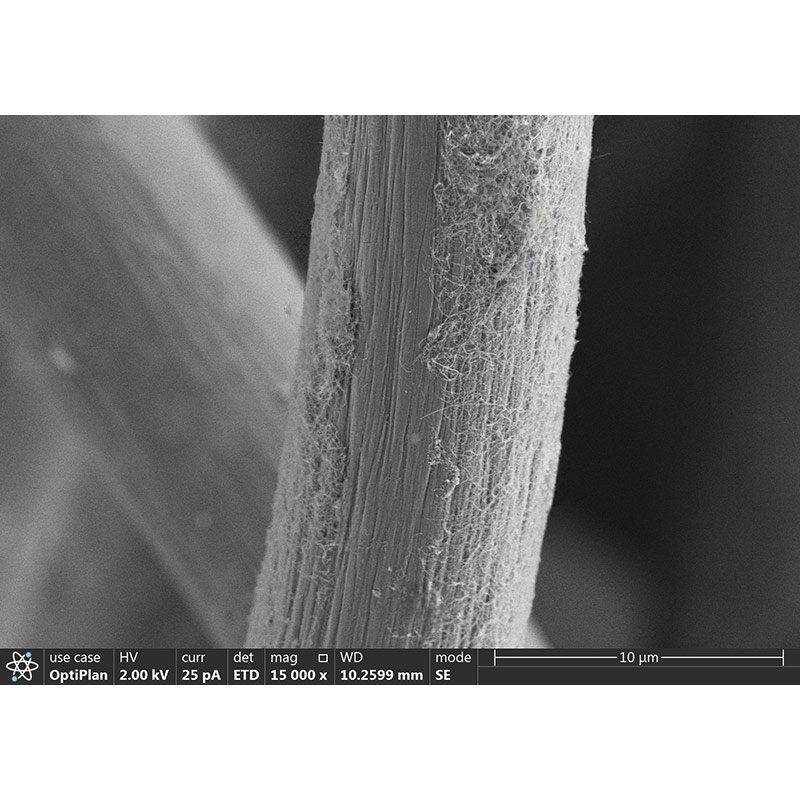

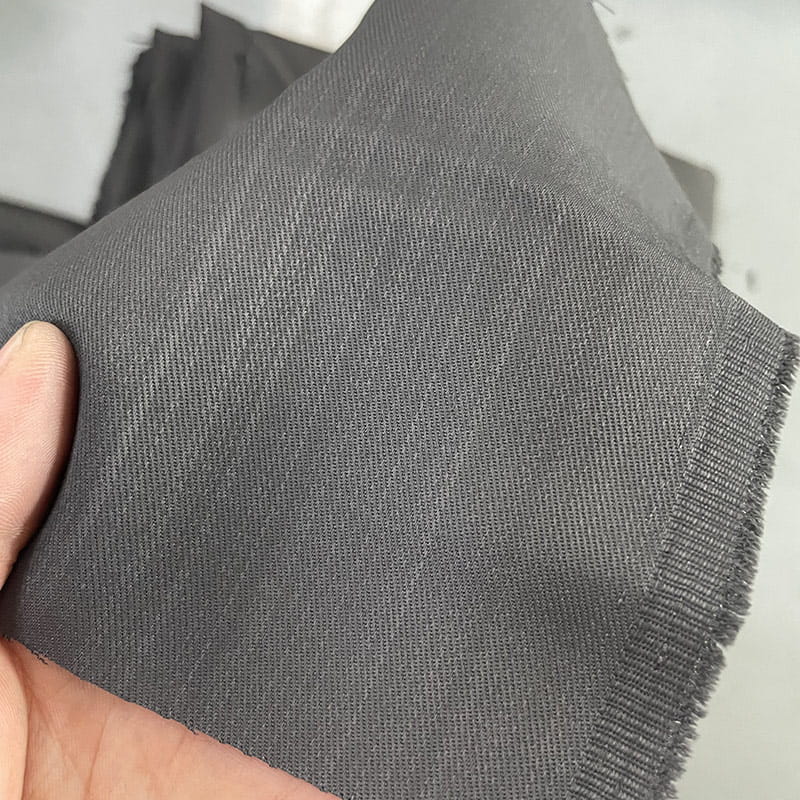

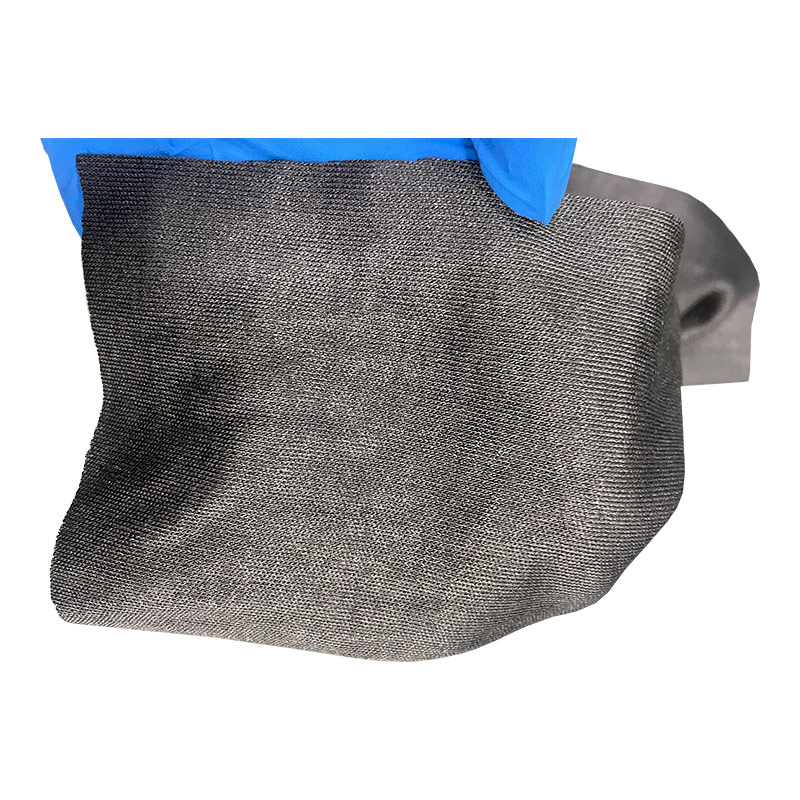

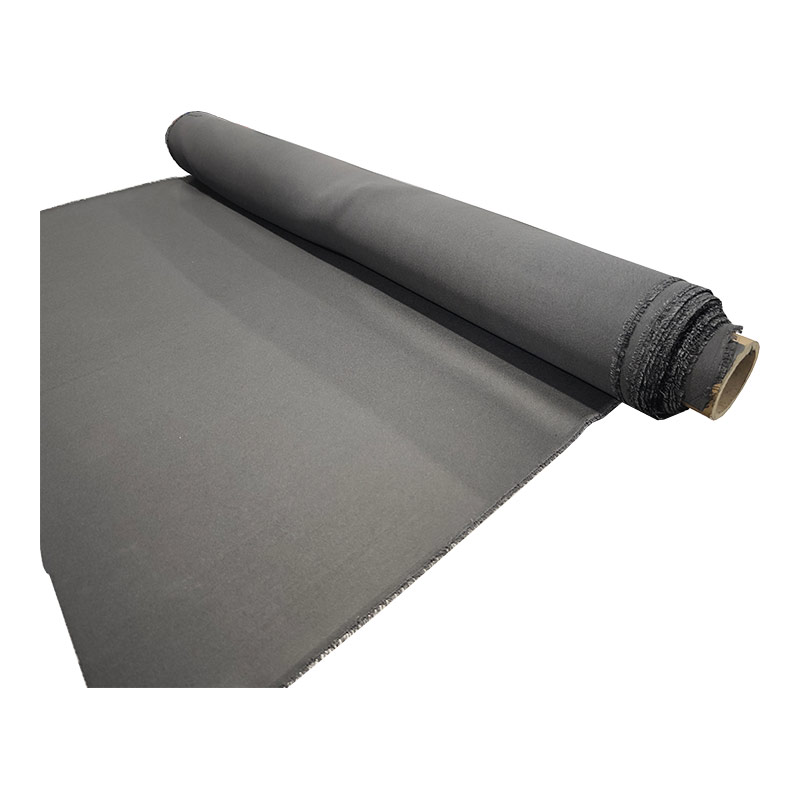

1. The electrode fabric developed independently by our company through gas-phase deposition is the first of its kind in the industry to be mass-produced using CVD technology. The specific surface area of the electrode can reach up to 100㎡/g at its maximum, with a regular specific surface area of 6-12㎡/g. The carbon nanotubes (CNTs) grown on the surface of carbon fibers endow the electrode fabric with permanent hydrophilicity without deactivation. The electrode material is grafted with pyrrole and pyridine structures that inhibit hydrogen evolution, further reducing side reactions. We can also customize different specifications of textile processes according to the actual needs of customers.

2. Our company independently developed a highly hydrophobic electrode fabric, which is the first in the industry to load both PTFE and CNTs together in a hydrophobic electrode fabric. The specific surface area of the electrode can reach up to 100㎡/g at its maximum, with a regular specific surface area of 9-15㎡/g. The electrode fabric is permanently hydrophobic. It can be widely applied in various electrolytic cells and fuel cell electrode materials.

- Product Details

- Contact Us

| Name | Unit | Electrode cloth | Remarks | |||

| ① | ② | ③ | ||||

| Thickness | mm | 0.6±5% | 0.8±5% | 0.9±5% | Other specifications can be customized according to customer needs |

|

| Model number | - | OEPLG-XX4235-7.5 | OEPLG-XX4542-7.5 | OEPLG-XX3543-7.5 | ||

| Density | g/cm³ | 0.3-0.4 | ||||

| Width | m | 1.3-1.5 | ||||

| Breaking strength | Radial | N | ≥20 | |||

| Zonal | ≥30 | |||||

| Thermal conductivity |

Vertical | W/m·k | 5 | |||

| Square resistance value |

Ω/口 | 0.12-0.4 | ||||

| Carbon content | % | ≥99.90 | ||||

| Liquid carrying rate | ×100% | 9 | 10 | 11 | ||

| Fiber shedding rate |

% | ≤0.5 | ||||

| Specific surface area |

m²/g | 9-15 | ||||

English

English  中文简体

中文简体