Polyacrylonitrile (PAN) -Based Carbon Cloth Graphite Cloth

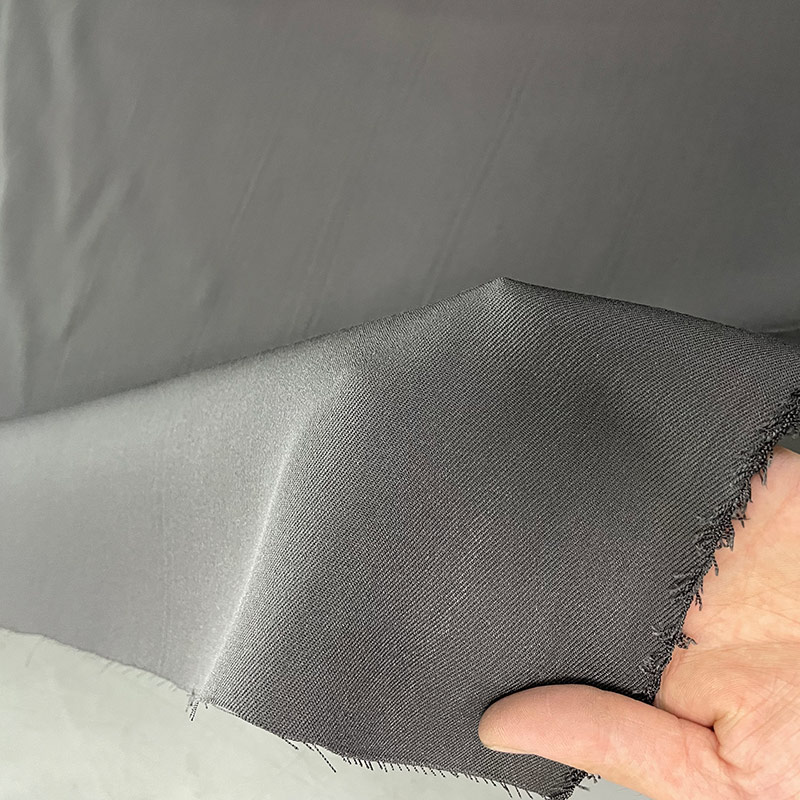

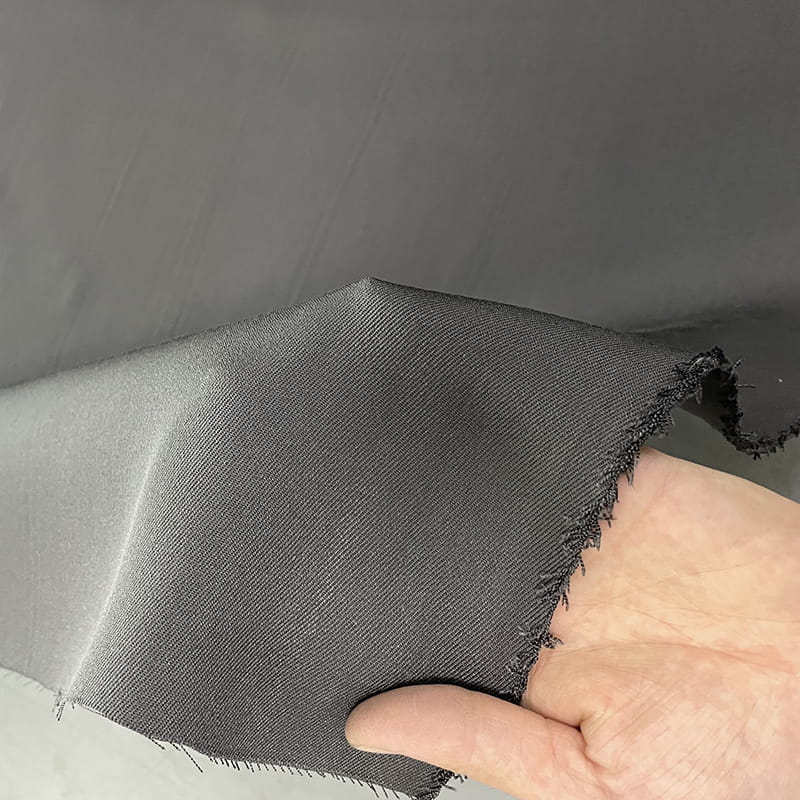

Carbonized fiber cloth with high carbon content is made by short-cutting and curling pre-oxygenated filament fibers, then spinning and weaving them, and finally carbonizing and graphitizing them. Depending on the application, it can be chosen whether to undergo graphitization treatment or not. The carbon content after carbonization is ≥95%, and the square resistance value is 0.3-2Ω. After graphitization, the carbon content is ≥ 99.8%, and the square resistance value is 0.1-0.5Ω. It features high electrical conductivity, high temperature resistance, wear resistance, and resistance to oxidation and erosion. It is widely used in various conductive, high-temperature isolation and friction materials, such as physiotherapy electrode plates, smelting glass pads, and brake pads for lure fishing wheels, etc.

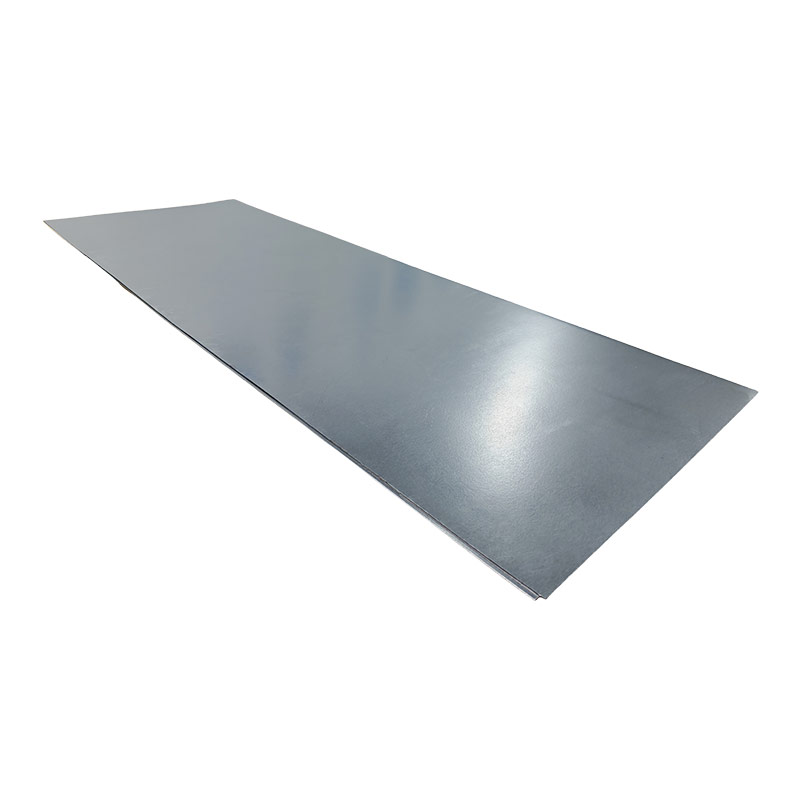

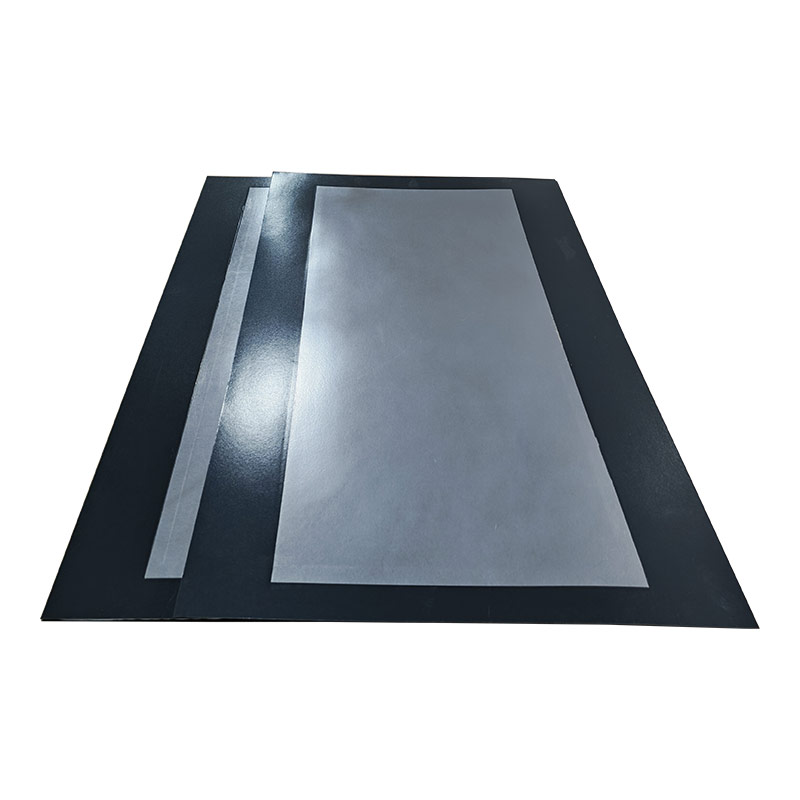

- Product Details

- Contact Us

| Name | Unit | PAN-Base | Remarks | ||

| Carbon cloth | Graphite cloth | ||||

| Thickness | mm | 0.3-1.5 | 0.3-1.5 | Other specifications can be customized according to customer needs |

|

| Density | g/cm³ | 0.35-0.45 | 0.3-0.4 | ||

| Width | m | 1.3-1.6 | 1.3-1.6 | ||

| Breaking strength | Radial | N | ≥20 | ≥18 | |

| Zonal | ≥30 | ≥27 | |||

| Square resistance value |

Ω/口 | 0.3-2 | 0.1-0.5 | ||

| Carbon content | % | ≥95.0 | ≥99.80 | ||

| Heat treatment temperature | ℃ | ≥950 | ≥1800 | ||

| Fiber shedding rate |

% | ≤0.5 | ≤0.5 | ||

| Specific surface area |

m²/g | 0.7-2 | 0.5-1.5 | ||

| Ash content | ppm | ≤2000 | ≤300 | ||

English

English  中文简体

中文简体