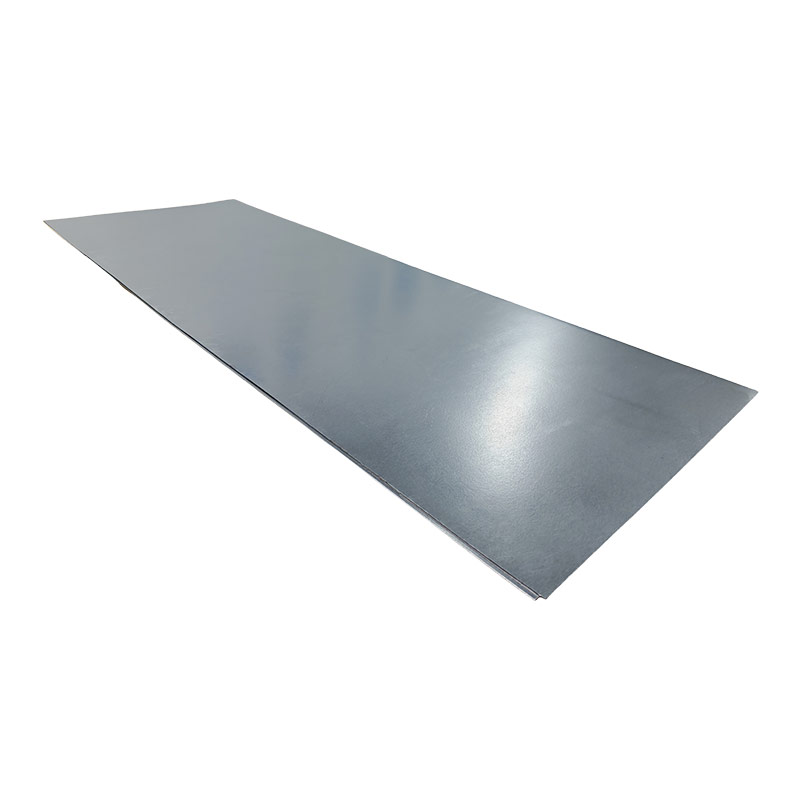

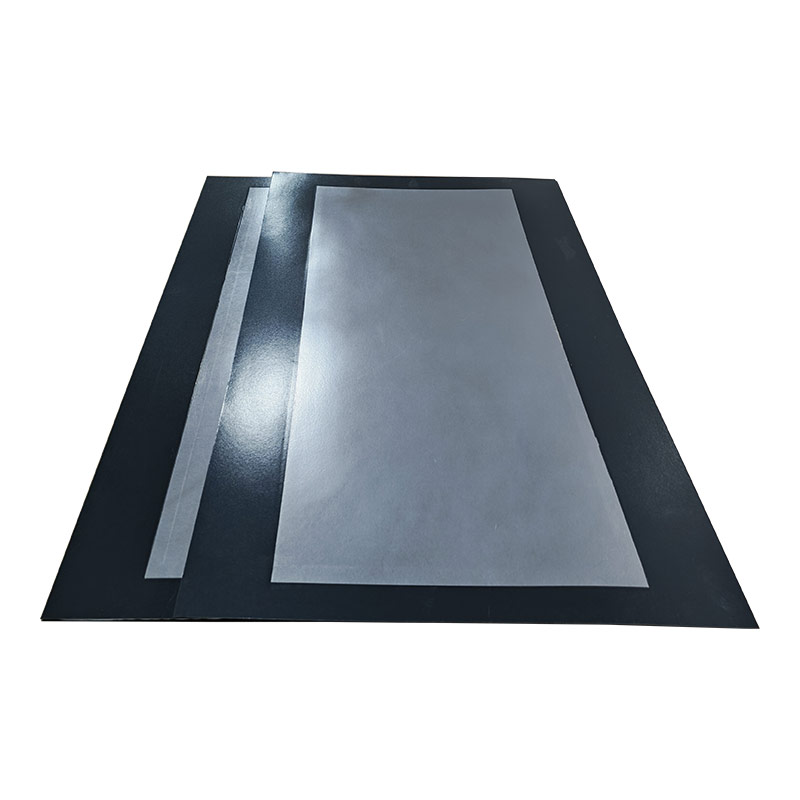

Viscose-Based Carbon Cloth Graphite Cloth

Carbonized fiber fabric with high carbon content is made from viscose fibers through short-cutting, curling, spinning and weaving, and then pre-oxidation, carbonization and graphitization. Depending on the application, it can be chosen whether to undergo graphitization treatment or not. The carbon content after carbonization is ≥95%. The carbon content after graphitization is ≥ 99.8%. It features high biocompatibility, high skin affinity, high bactericidal and antibacterial properties, and high adsorption. It is widely applied in various fields such as medical care and wartime trauma treatment.

- Product Details

- Contact Us

|

Name |

Unit |

Rayon-Base |

Remarks |

||

|

Carbon cloth |

Graphite cloth |

||||

|

Thickness |

mm |

0.3-1.5 |

0.3-1.5 |

Other specifications |

|

|

Density |

g/cm³ |

0.25-0.35 |

0.2-0.3 |

||

|

Width |

m |

1.3-1.6 |

1.3-1.6 |

||

|

Breaking strength |

Radial |

N |

≥10 |

≥9 |

|

|

Zonal |

≥15 |

≥13 |

|||

|

Square |

Ω/口 |

2.0-10.0 |

0.8-2.0 |

||

|

Carbon content |

% |

≥95.0 |

≥99.80 |

||

|

Heat treatment temperature |

℃ |

≥950 |

≥1800 |

||

|

Fiber |

% |

≤0.3 |

≤0.3 |

||

|

Specific |

m²/g |

5-10 |

3-7 |

||

|

Ash content |

ppm |

≤300 |

≤300 |

||

Related Products

-

Polyacrylonitrile (PAN) -Based Carbon Cloth Graphite Cloth

-

Viscose-Based Graphite Felt

-

Carbon Fiber Reinforced Composite Flexible Graphite Bipolar Plate

-

Carbon Fiber Reinforced Composite Flexible Graphite Bipolar Plate With Welded Edges

-

Electrode Cloth

-

Carbon Fiber Reinforced Carbon-Plastic Bipolar Plate

English

English  中文简体

中文简体