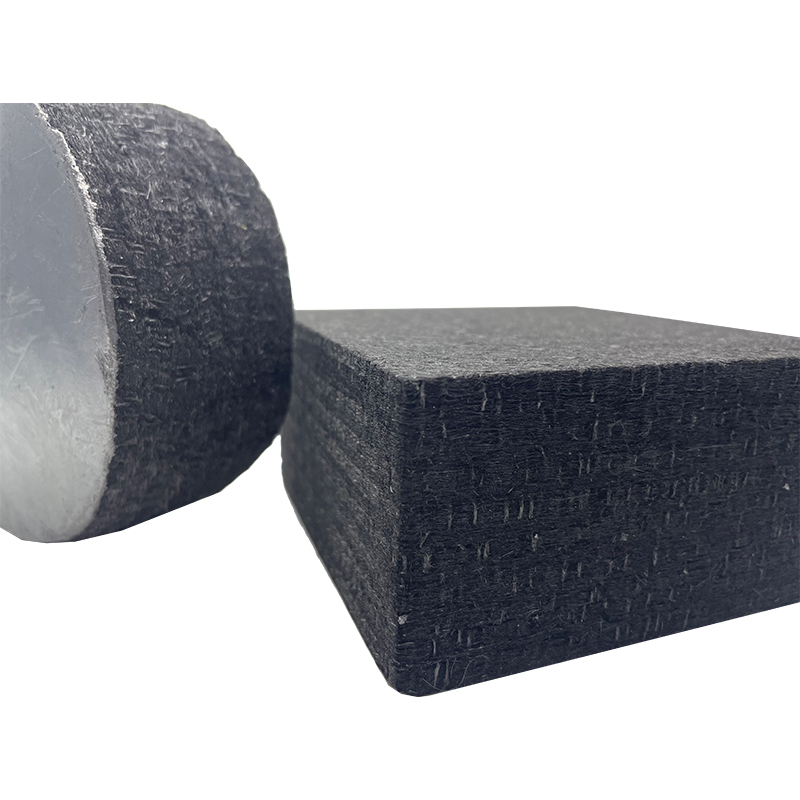

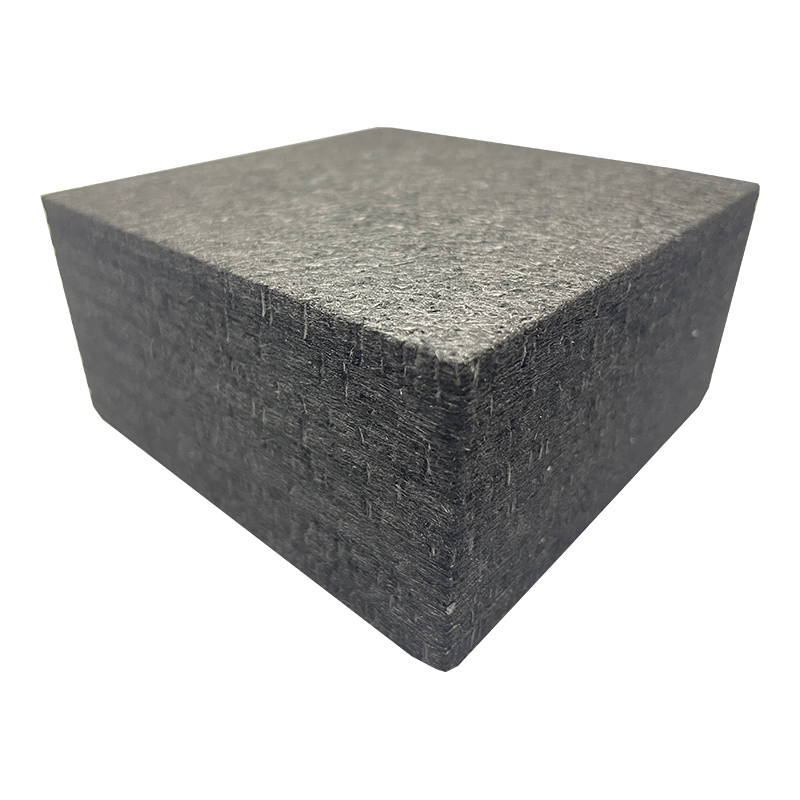

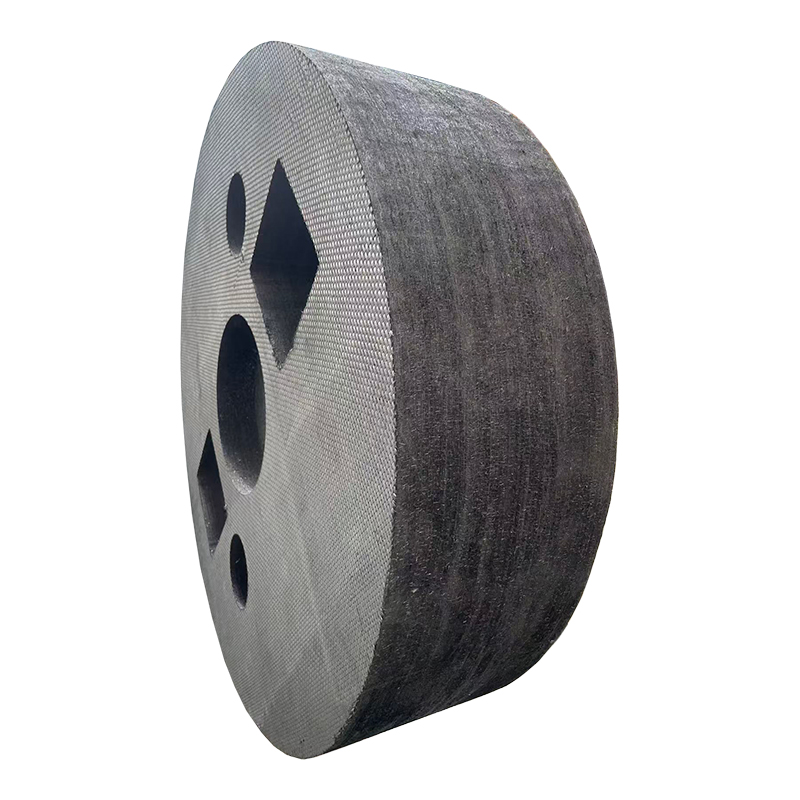

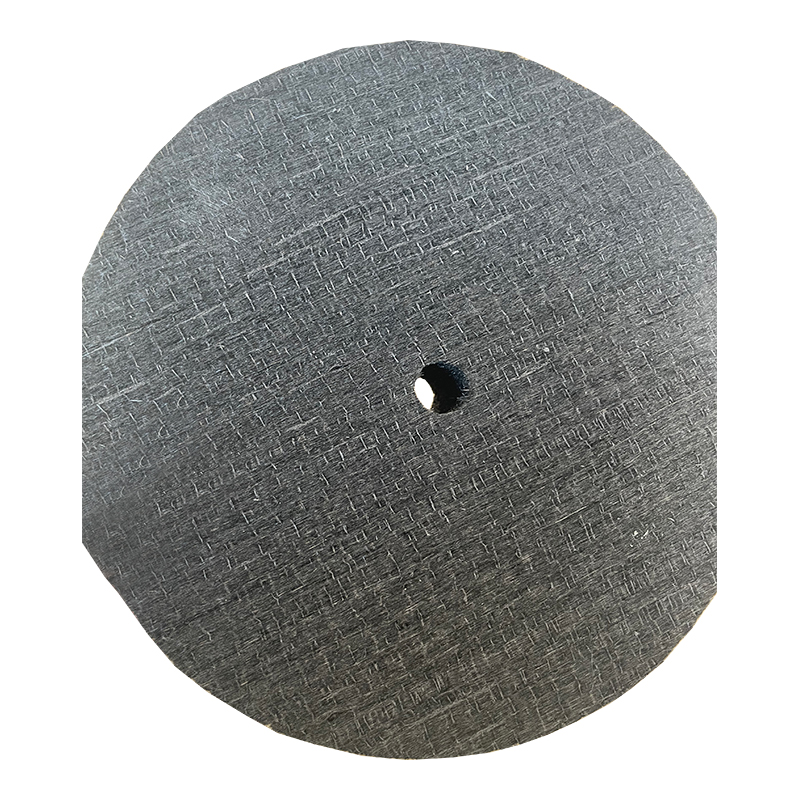

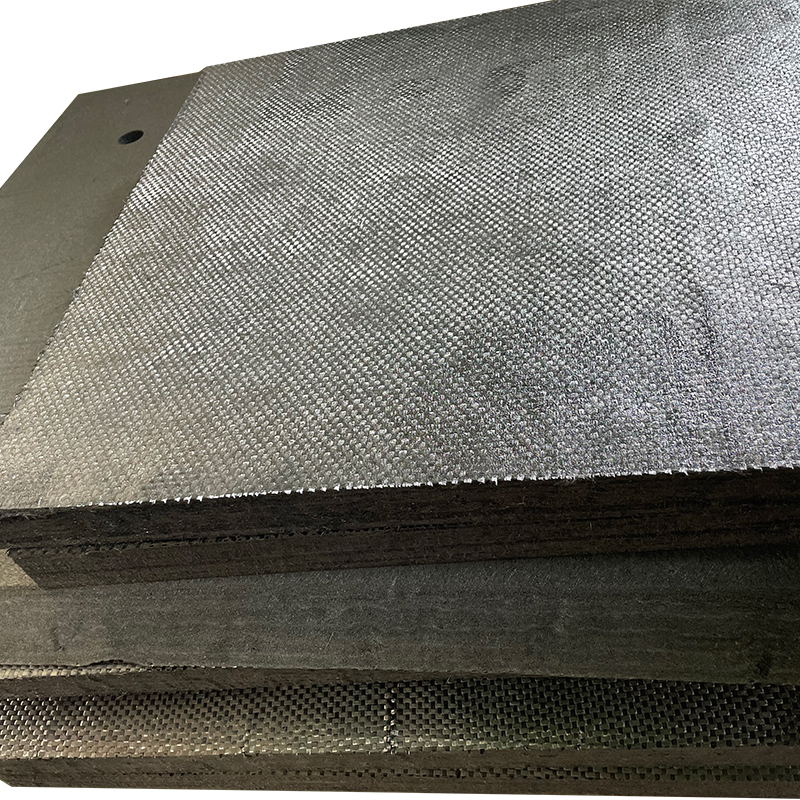

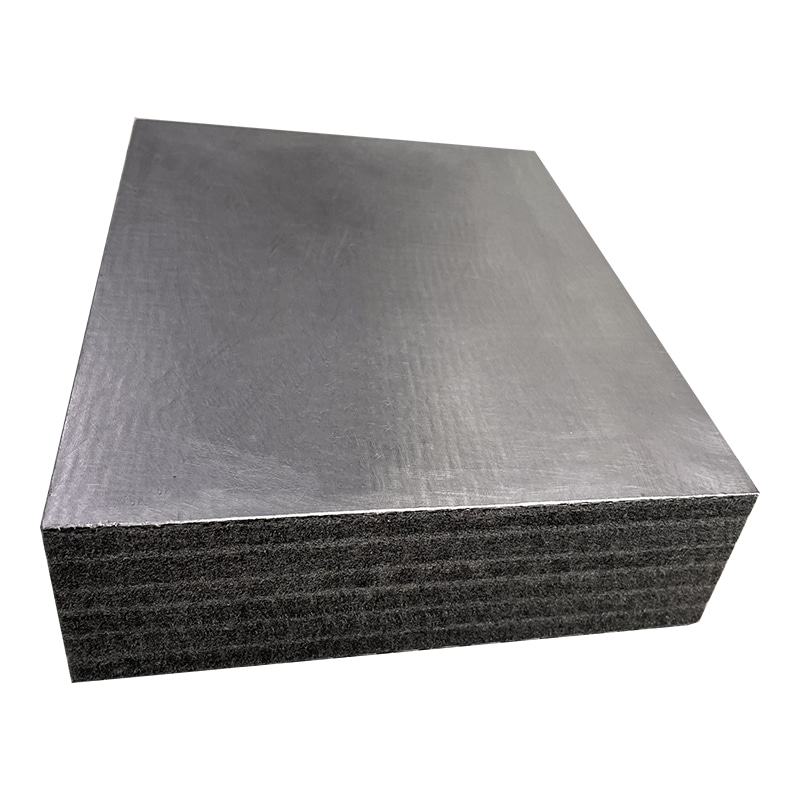

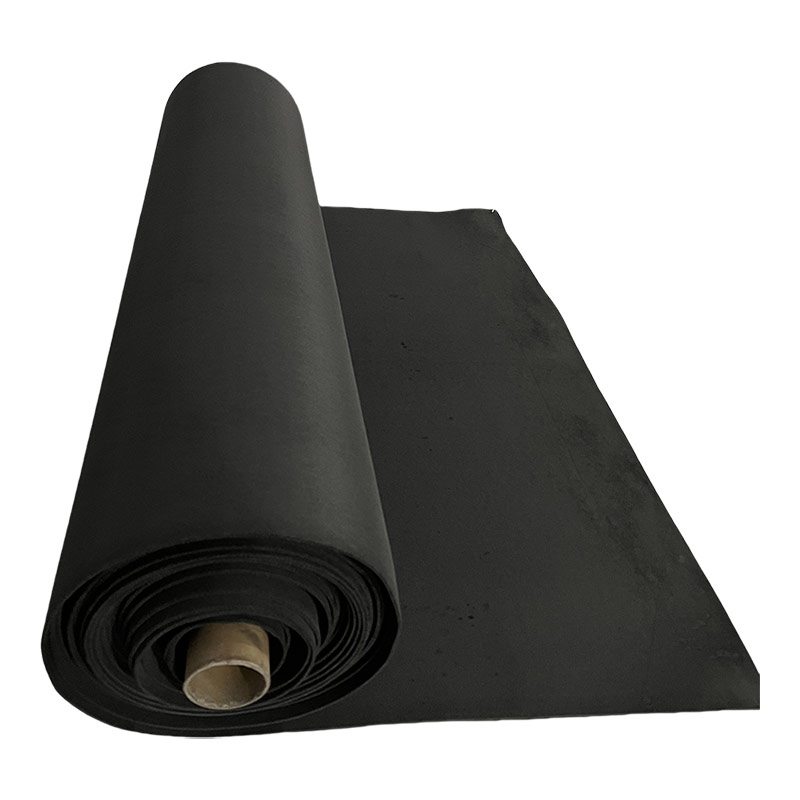

Integral Needle-Punched Cured Felt

This product is a hard thermal insulation component made by laying high-strength carbon fibers and needling them into a web matrix, then layering the web matrix and needling it into a preform, followed by resin penetration, curing the resin at high temperatures, and finally graphitization at a temperature of ≥1800℃. It features strong rigidity, self-support, low specific gravity, no short fiber shedding, low thermal conductivity, and a service temperature of ≤3200℃. It is applicable to various furnace types such as high-pressure gas quenching furnaces, pressure sintering furnaces, silicon carbide recrystallization furnaces, monocrystalline silicon pulling furnaces, and polycrystalline silicon ingot casting furnaces. It can be provided in various shapes such as plates, discs, and cylinders. It has a long service life and is easy to install and dismantle. Thermal conductivity ≤0.2W/m·k.

- Product Details

- Contact Us

|

Name |

Unit |

Integral needle-punched cured felt |

Remarks |

|

|

Thickness |

mm |

20-300 |

Other specifications |

|

|

Density |

g/cm³ |

≤0.18 |

||

|

Width/Diameter |

mm |

≤1800 |

||

|

Length/Height |

mm |

≤2400 |

||

|

Extension strength |

Mpa |

≥1 |

||

|

Compressive strength |

Mpa |

≥2 |

||

|

Thermal conductivity |

W/m·k |

1200℃ |

≤0.16 |

|

|

1500℃ |

≤0.2 |

|||

|

Carbon content |

% |

≥99.80 |

||

|

Heat treatment temperature |

℃ |

≥1800 |

||

|

Ash content |

ppm |

≤300 |

||

English

English  中文简体

中文简体